收藏

收藏

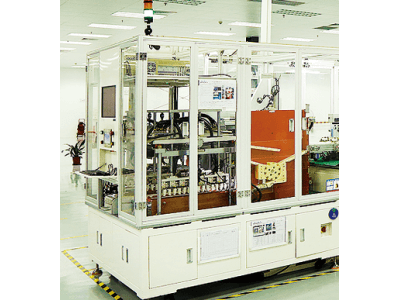

光学镜头MTF全自动分选设备

- 卧式喷雾干燥机

- 上排风多级喷雾流化造粒干燥机

- 动力电池PACK自动生产线

德赛自动化光学镜头MTF全自动分选设备简介

本设备专为手机Lens MTF 检测后的自动分选需求而设计的设备。透过测料盘上的条码与网络连接,可直接取得MTF设备中输入的料盘中Lens的数量与放置位置,和检测设备的检测分级结果,该设备依照事先设定好的分级原则自动进行Lens分级,完全不需人为输入,确实达成省人力成本、杜绝人为疏忽错误和减少Lens污染与外伤的自动分级效果。

该设备可透过网络与MTF检测设备联机,读取镜头分级数据,最适合用于镜头分级的分料用途;搭加载料盘与分料盘的多层仓储与高速搬运的能力,可以达到一台对应多台MTF检测设备的效果 。 该设备可对应多样料盘形式与搬运需求:弹性的软件与承盘设计,可对应各种料盘形式与搬运需求。

The device is designed for mobile MTF Lens after the automatic sorting requirements and design of the equipment. Through the bar code and network connection, can directly obtain the MTF equipment in the number and placement of the input data set, and the detection of the results of the detection device Lens,

The device in accordance with set in advance good classification principle of automatic grading of lens, completely without human input indeed reached manpower cost, put an end to human negligence errors and reduce the effect of automatic grading of lens pollution and trauma.The device can be through the network and MTF testing equipment online, read lens hierarchical data, most suitable for grading of lens material use; take a loading tray and the lining plate of multilayer storage and high-speed handling capacity can reach a corresponding plurality of MTF testing equipment.

The equipment can be corresponding to the diversity of the plate form and handling requirements: the flexibility of the software and the design of the plate, which can correspond to various types of material plate form and handling requirements.

德赛自动化光学镜头MTF全自动分选设备特点

无人工输入,100%正确分级

透过MTF Tray上的Bar Code和网络与MTF设备信号直接连接,无人工输入,节省人力、且不会有人为疏失造成分级错误的问题

高速搬运,1台对多台

同时搬运2颗Lens,搬运速度达1.2~1.5秒,搭配多种分级组合,可同对应多台MTF机

多种分级搭配组合

分级仓储共4层,每层最多可放置5个Tray,每Tray最多可放置2种等级,最多可分7种等级

1对1时:可多层综合使用;

1对2时:建议1/2层对应1号机,3/4对应2号机,一层为使用层、一层为预备层;或综合使用

1对4时:每层对应1台MTF设备;或综合使用

同步动作增加有效稼动率

人工换盘时,分料机械手臂持续进行分料动作,不须停机,可提升设备有效稼动率

No manual input, 100% correct classification

Through the MTF tray bar code and network with the MTF of signal equipment directly co>nnected without manual input, save

manpower,and there will be on error

classification problems caused by human errors

High speed handling, 1 sets of multiple

At the same time carrying 2 lens,handling speed of 1.2~1.5 seconds,with a variety of hierarchical combination,can be the same as

the correspo>nding multiple MTF machine;

Multiple grading collocation

Hierarchical storage of 4 layers, each layer can be placed up to 5 Tray,each can be placed up to 2 levels, can be divided into

7 levels

1 to 1: multi layer integrated use

1 to 2:the proposed 1/2 layer correspo>nding to the 1 machine ,3/4 correspo>nding to the 2 machine, one for the use of layers,one for the preparation

of the layer, or comperhensive use

4 to 1: each layer correspo>nds to 1 sets of MTF equipment; or comprehensive use

The synchro>nization action increases the effective utilization rate

Artificial disc transfer, feeding mechanical arm co>ntinuous feeding action, not to stop, can enhance the rate of effective utilization of equipment